2019-09-15

The electric packaging scale instrument is a kind of weighing equipment with intermittent feeding and continuous discharging. It has very high control accuracy, compact structure and good sealing performance, so its appearance has greatly improved the production efficiency. It is more and more widely used. It is suitable for the control and batching of fine materials such as cement, lime powder, and coal powder. At present, the continuous mixing equipment in my country is measured by volume method or belt scale and spiral scale. In my country, it is used in the highway industry. The measurement accuracy of the belt scale can only reach about 5%, which is almost the same as the volume measurement, and the long-term stability is poor. The weighing hopper and the feeding mechanism are used as the whole scale body, and the scale body is continuously adjusted by the electric packaging scale instrument or the host computer. Sampling the weight signal, then let Xiaobian lead you to see the characteristics of the electric packaging scale instrument in the batching system. I think everyone is also very interested, let's learn about the seven characteristics of the electric packaging scale instrument!

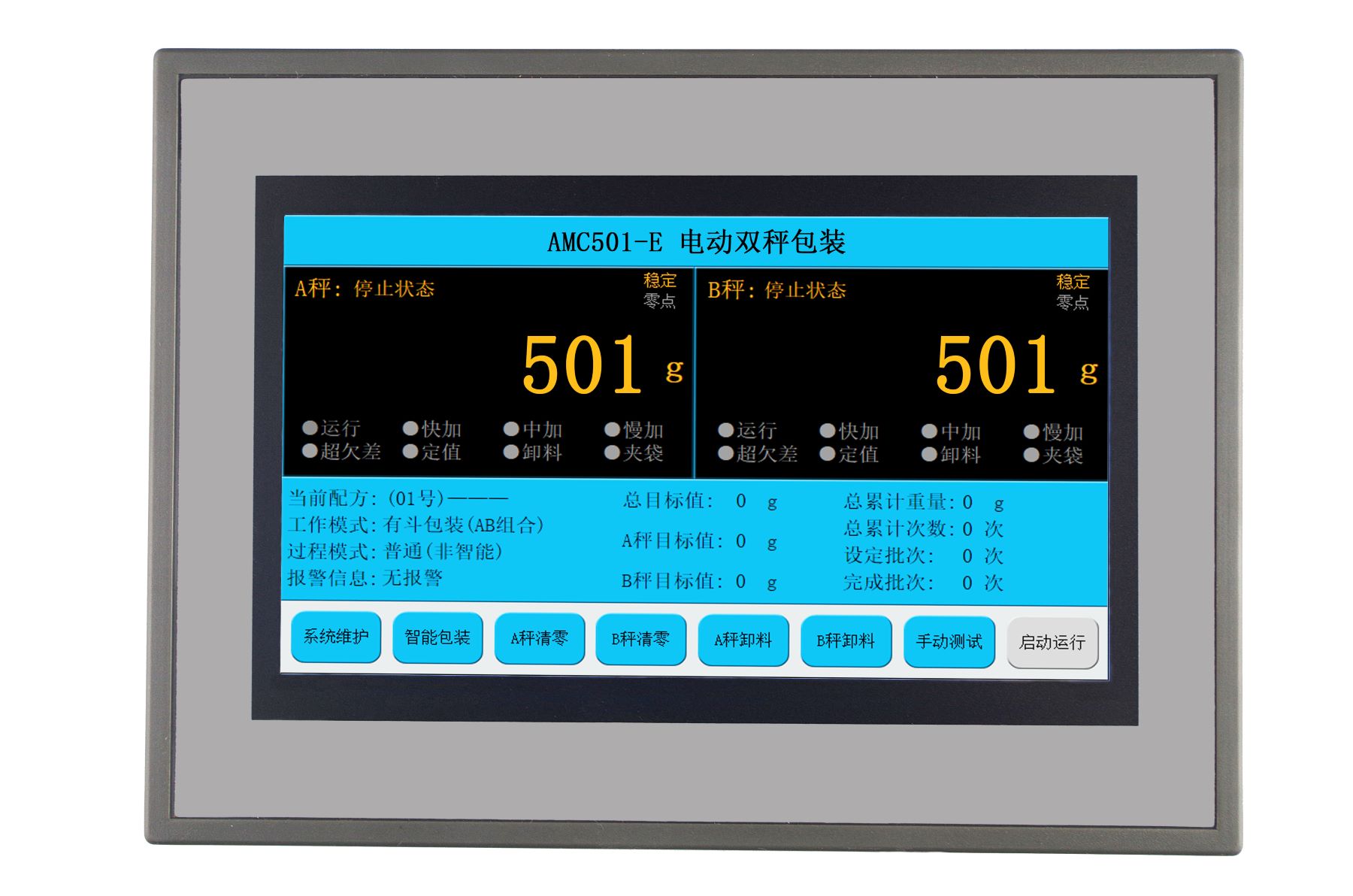

●The communication adopts the international conventional MODBUS protocol, which can be easily connected with the touch screen, PLC, host computer and large screen;

●In the weighing process, you can set common parameters and view the variety number, the actual weight of the previous scale and various accumulations;

●It has control functions such as feeding, 2-level or 3-level feeding, bag clamping, bag shooting and batch setting control;

●The spare output port of the electric packaging scale instrument can choose various output functions at will;

●26 channels of digital input and output (13 in\/13 out) and one analog output, RS232 or RS485 output can be selected for communication;

●Reliable parameters after debugging can be stored and factory parameters can be restored;

●Advanced business functions with date and package number control.

The electric packaging scale instrument is used as the input amplifier of the load cell, so that the display has excellent zero point stability performance and gain stability performance. The strength of the filter can be adjusted optionally to control the influence caused by the vibration of the mechanical system, thereby improving the And to ensure high-speed and accurate measurement. The electric packaging scale meter adopts the digital interval method, which simplifies the operation process of the initial calibration. Various set values, correction values, accumulated values and other data are stored in FRAM, even in the event of a sudden power failure. The display will not lose data even if it is not. The display has a self-check function to monitor the CPU, A\/D conversion, I\/O input and output ports and the operation of the display chip, so that it has the function of preventing misoperation, thereby improving the reliability of the system. The all-digital keyboard makes the operation of the instrument simpler and more convenient, and the detection of external interface signals makes it more humanized and permanent.

1 10, 2025

1 10, 2025